Most Common OSHA Violations

The most common violations that are seen each year almost the same. Following is a list of a number of OSHA Violations.

-

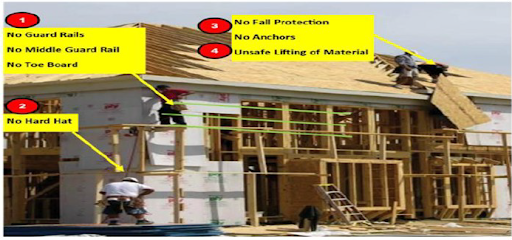

Fall Protection

One of the most common and leading causes of deaths in consecution and other industries is falling. The statistics revealed by OSHA have shown that almost 33% of the deaths caused in private sector are because of falling and these alarming numbers have scared almost everyone. In such a situation, all we need to do is to follow OSHA standards in terms of falling.

Employers are responsible for setting up controls in order to protect their workers from any kind of fall related to overhead platforms or elevated workplaces. This mainly involves the planning of jobs in a careful way and providing the workers with safety equipment. Moreover, the ladders used by the workers must be checked on regular basis and safety alarms should also be installed in case of any emergency.

-

Hazard Communication

Most of the companies these days are using hazardous and toxic chemicals which can badly affect the health of their employees. These companies include fertilizer industries, cement industries and other such industries. So, the risks associated with these chemicals must be communicated to the workers in order for them to stay safe and alert. They must be provided with trainings to understand what to do in case of an emergency. The Hazard Communication Standards made by OSHA are the best in terms of awareness for the workers regarding these harmful chemicals.

All the chemicals present in the laboratory must be labeled with their names so that a worker may think twice before touching or using it. Moreover, employers must have a record of all such chemicals present at the workplace which will ultimately help their workers. This is the only way the employers can save a lot of precious lives.

-

Scaffolding

The scaffolding security has a key role to play in the prevention of falls. The scaffold standards made by OSHA require scaffolds along with their components for supporting the weight of worker and a minimum of four times the intended load. The most common causes of such accidents include flooring collapses or defective scaffolds. Employers must be responsible in keeping a check and balance of scaffolding and ensure that they are working according to the OSHA standards which include the usage of guardrails or fall arrest systems.

-

Lockout

Lockout or Tagout is mainly applied to all the situations where energy is released while starting up an equipment. This energy can surely harm the workers. In such a situation, Lockout procedure can help you in the prevention of a number of serious accidents including:

- Wiring short which can shock the workers

- A worker who is working on a valve

- Releasing a conveyor belt which was jammed can cause a serious injury.

Proper training sessions must be arranged for the workers in order to aware them regarding lockout procedure. Machinery present in an industry must be equipped with a lockout or tagout device. Once such a device is placed there, only the one (worker) who used it will be able to remove it.

-

Respiratory Protection

One of the most common violations seen in almost all the industries is the respiratory problem. Such problems are caused when the breathing air is contaminated with toxic and harmful things including dust, smoke, vapors or fumes. When the employers fail in taking precautionary measures for the safety of their workers, they receive an OSHA violation. The OSHA Standards include a number of types of respirator and their usage in different situations. Moreover, employers must create a written program regarding respiratory protection for the sake of awareness among the workers.

-

Ladders

Most of the deaths occurring in construction industries are mainly because of the ladders. Experts and statistics reveal that lack of experience and lesser number of safety trainings are the major causes of such accidents. The OSHA Standards made for Ladders must be taken into account and workers should be aware of those standards. The best possible practices include the selection of perfect ladder for the work you’re doing, and their placement in accurate positions. This will ensure the safety of the workers.

-

Machine Guarding

Workers who’re working in different industries have to face so many hazards when tripping devices, electronic devices and other machine guarding methods aren’t employed in a proper way. These guards must be attached with all the machines in order to ensure the safety. Moreover, employers must arrange training sessions regarding OSHA Standards for Machine Guarding. In this way, it can be made sure that the usage of these guards is quite simple and beneficial. Proper equipment should be provided for guarding and let your workers know about the accurate way to attach or detach these machine guards.

-

Protection for Eyes and Face

Statistics have revealed that almost 2000 or more workers in the United States face an eye injury on daily basis and medical treatment is required for such injuries. Small sized particles which strike the eyes including dust, metal silvers, drywall or nails are the major causes of these eye injuries. Moreover, the toxic chemicals used in the industry are also responsible for burning the eyes or face of a worker.

Employers must provide their workers with proper PPE for the prevention of such injuries. Guards on machines along with the controls can help in preventing these injuries. Moreover, glasses can get the job done too if the employers incorporate the required prescriptions in the designs of these glasses. Training sessions must also be conducted in order to let the workers know about the OSHA Standards regarding Eye and face injuries.

Requirements for Training

Falls have always been playing a huge role in injuries. It isn’t a big deal at all for OSHA to penalize all such businesses which do not follow their standards. However, employers must provide their workers with training programs for awareness purposes. The training include the erection, maintenance and inspection of protection systems. Moreover, workers should also be aware of the safe operation of these systems, line systems, control zones and guardrails. Besides this, employers should also award certificates to the trainees in order to encourage them.

How to Prevent these Violations and Accidents?

OSHA Violations along with the injuries can be avoided quite easily just by proper safety trainings. Once you train your workforce regarding the safety standards, you can get rid of OSHA fines as well. Otherwise, employers may have to pay a minimum of $14000 for a single violation. Moreover, if the industry fails to resolve the issue even after paying the fine, they’ll have to pay the same amount each day until the issue is resolved.

States which have their own safety plans charge maximum amount in case of any violation. However, conducting proper safety and health training programs will ensure the safety of your workers which will ultimately avoid any violation.

0 Comments